Cell Testing and Evaluation

Test Facilities

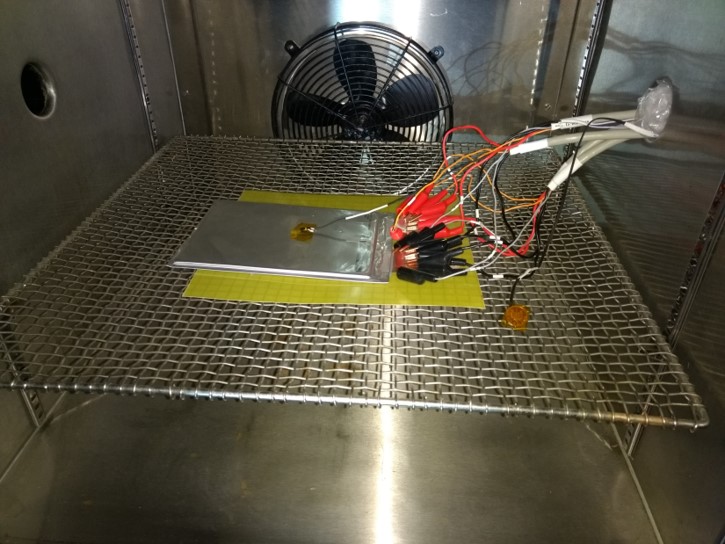

EVPARTS has a range of Lithium cell cycle testing equipment which can be used to provide cell level high frequency drive cycle simulation, cell performance characterisation, cell lifecycle evaluation or pack cell grading. The cell cyclers are combined with an environmental chamber to provide full control over testing temperature and humidity. Test fixtures are available for cylindrical and pouch format cells that ensure appropriate cell compression is maintained during testing.

We have two cell test cyclers from the latest generation of Neware battery testing equipment, a BTS4008-5V-10A and a BTS8002-5V-100A.

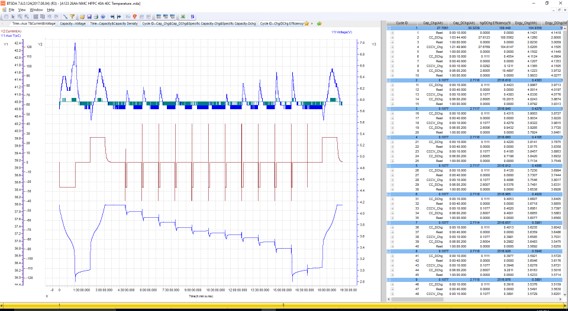

The BTS4008 unit has 8 single cell 10Amp charge/discharge channels. The channels can be connected in parallel combinations to deliver up to 40Amps. It can be used for HPPC (hybird pulse power characterisation) for lower capacity cells, step programmable drive cycle testing and life cycle evaluation as well as cell grading.

The Unitemp environmental chamber can operate from -40°C to +140°C and 0% to 100% relative humidity. The environmental chamber can be programmed to follow temperature and humidity profiles during lithium cell testing.

An Applent AT526B Battery AC Internal Resistance Meter can be used to validate the cell characteristics before and after testing as required.